Within the hydrogen energy industry chain, compressors are acclaimed as the "heart" of the storage and transportation system. Their technical performance is directly related to the cost and widespread adoption of hydrogen energy. For a long time, high-end ionic liquid compressor technology has been monopolized by foreign enterprises. Domestic companies not only had to bear high import costs but were also constrained by technological barriers. Against this backdrop, Yantai Dongde Industrial, through its independently developed Ionic Liquid Sealed Compressor, has achieved a leap from technological catch-up to partial leadership, laying a solid foundation for China's autonomous and controllable hydrogen energy equipment.

Technical Background: The Pain Point of "Bottleneck" Technologies in High-End Equipment

Ionic liquid compressors, due to their characteristics of high pressure and large displacement, have become high-end equipment in the field of hydrogen storage and transportation. However, their core patents have long been controlled by foreign companies. Domestic downstream enterprises not only had to shoulder enormous import expenses but also faced limitations in equipment adaptability and service responsiveness. With the expansion of China's hydrogen energy industry scale, according to forecasts from theChina Hydrogen Energy and Fuel Cell Industry White Paper, annual hydrogen demand is projected to reach 37.15 million tons by 2030. Traditional compressors can no longer adequately meet the high-pressure and high-efficiency demands of storage and transportation. Breaking the technology monopoly and developing domestically controllable, self-reliant compressors has become a critical link in the development of the industry chain.

Innovation Highlights: A Technological Leap Marked by a Single Word Difference

The Ionic Liquid Sealed Compressor developed by Dongde Industrial, although differing from the traditional "ionic liquid compressor" by only a single word, has achieved multiple technological breakthroughs:

High-Performance Parameters:

Discharge pressure reaches over 100 MPa, single-unit displacement reaches 50,000 standard cubic meters, with a compression ratio exceeding 50:1. It can boost hydrogen pressure from 1.6 MPa to 100 MPa, significantly enhancing storage and transportation efficiency.

Breakthrough in Sealing Technology:

Utilizing a crankshaft connecting rod structure and circulating ionic liquid sealing technology, it achieves dynamic sealing, lubrication, and cooling of the piston rings via the ionic liquid, realizing zero hydrogen leakage within the compression chamber. This technology can also be extended to pressurization scenarios involving toxic, flammable, explosive, or other special gases.

Energy Efficiency Optimization:

The thermal stability and cooling properties of the ionic liquid bring the compression process close to an isothermal state, reducing comprehensive energy consumption by 20%-30%. The overall unit operating energy consumption is below 1.75 kW/kg, saving over one million kilowatt-hours of electricity annually.

Application Scenarios: Solutions Covering Multiple Fields

Based on core technological innovations, this equipment has established an application matrix covering the entire hydrogen energy industry chain:

Green Hydrogen Production and Storage:

In electrolytic water hydrogen production scenarios, it enables direct high-pressure hydrogen filling, meeting the demand for multiplied single-stack output.

Hydrogen Refueling Stations:

Developed integrated hydrogen production and refueling station compressors, combining hydrogen production and refueling equipment into a single unit with a discharge pressure of 45 MPa, suitable for high-capacity refueling station requirements.

Petrochemical Industry:

Supports different pressurization modes such as long-tube trailer and pipeline hydrogen transportation, applicable to scenarios including chemical synthesis and filling operations.

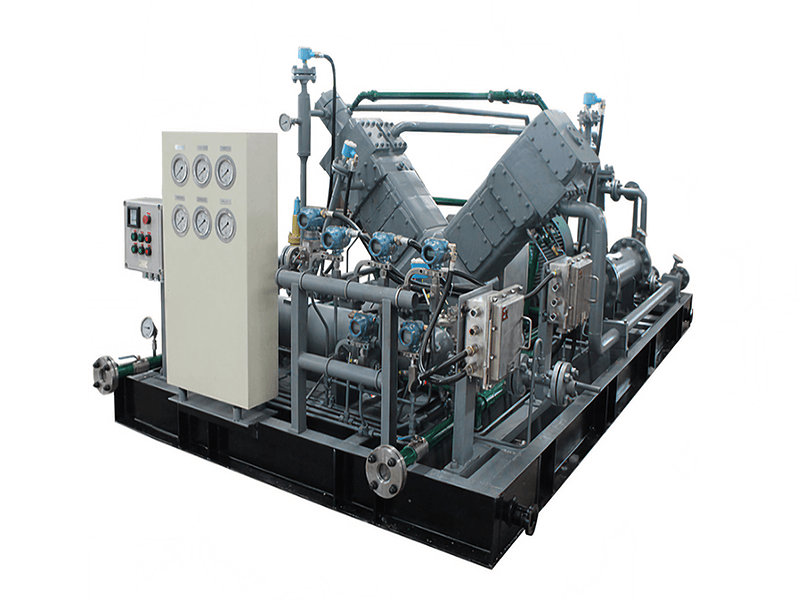

Furthermore, through skid-mounted integrated design, the equipment can be flexibly deployed in various complex environments.