When you retrieve a chilled drink from a refrigerator or enjoy cool air from an air conditioner, have you ever considered the "power source" behind these daily conveniences? In factory workshops, pneumatic tools operate with rhythmic precision; in chemical plants, various gases are accurately conveyed; even the steady operation of hospital ventilators—all these rely on a seemingly humble yet vital piece of equipment: the compressor. Functioning as the "heart and lungs" of industry, it continuously compresses and transports gases, infusing modern life and production with silent yet potent energy.

I. What is a Compressor? – The Fundamentals

A compressor, as the term implies, is a machine designed to increase gas pressure and convey it. Its core principle is to perform mechanical work to reduce gas volume, thereby elevating its pressure and density. Based on the compression method, compressors fall into two primary categories: positive displacement and dynamic.

Positive displacement compressorsoperate by physically reducing the volume of a confined chamber to compress the gas, akin to squeezing air from a balloon. Typical examples are piston and screw compressors. Gas is drawn into a chamber of variable volume; as this volume decreases, pressure rises progressively until the gas is expelled.

Dynamic compressorsutilize a high-speed rotating impeller to impart kinetic energy to the gas, which is then converted into pressure energy within a diffuser. The centrifugal compressor exemplifies this type. Similar to a fan propelling air but far more sophisticated in design, it achieves substantial pressure rise in a continuous flow.

These two categories serve distinct applications, together forming the technical foundation of industrial gas compression.

II. Mainstream Types: Piston, Screw, and Centrifugal

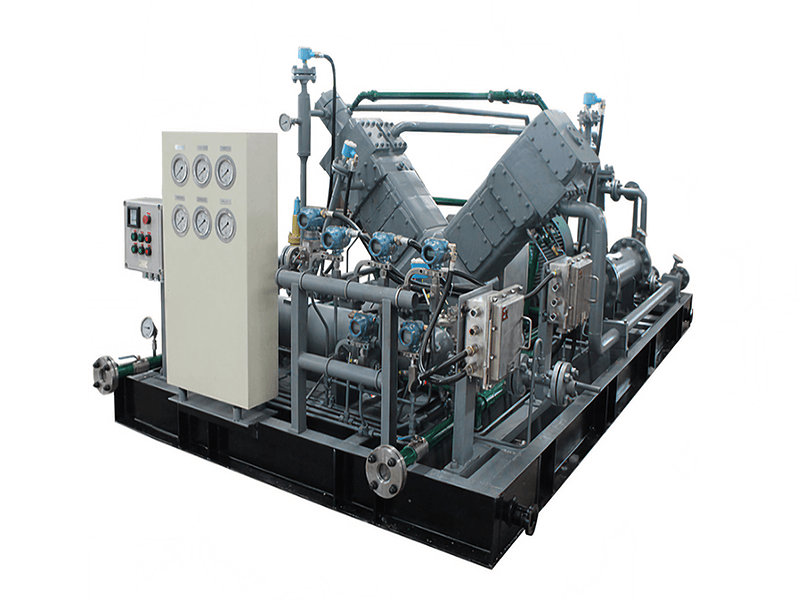

Thepiston compressoris among the oldest and most widespread types. It uses the reciprocating motion of a piston within a cylinder to cyclically alter the chamber volume, accomplishing intake, compression, and discharge. Valued for its simple design and broad pressure capability, it is common in applications with small-to-medium flow rates at moderate-to-high pressures, such as small workshop air supplies or refrigeration units. However, inherent reciprocating forces result in significant vibration and pulsating airflow.

Thescrew compressoremploys a pair of intermeshing rotors. As they rotate, the volume between their teeth changes continuously, enabling steady intake, compression, and exhaust. Known for smooth operation, minimal vibration, continuous discharge, and easy capacity modulation, it is extensively used for industrial air power and process applications, particularly suited to medium flow and pressure demands.

Thecentrifugal compressorrepresents the dynamic type. Gas enters a high-speed impeller, gaining kinetic energy that is subsequently transformed into pressure energy within the diffuser. It excels in handling large-volume flows, offers compact design and smooth operation, and avoids lubricant contamination of the medium. Consequently, it plays a central role in critical processes within large-scale air separation plants, petrochemical complexes, and metallurgy—for instance, as the main blower in catalytic cracking units or for air boosting in major air separation facilities.

III. An Indispensable Role

The compressor's function extends well beyond merely "supplying compressed air." It is a prerequisite for normal operation across countless industries, integral to both industrial and daily life.

Withinindustry, compressors act as the "heart" of pneumatic systems. They power clamps, sprayers, and control valves on production lines. In chemical and refining operations, they compress, convey, and synthesize process gases like ammonia and hydrogen. In energy sectors, they enable natural gas pipeline transmission, supply combustion air to gas turbines, and operate braking systems in wind power generation.

Indaily life and advanced technology, compressors are equally ubiquitous. Household refrigerators and air conditioners depend on them for the refrigeration cycle. They are essential for inflating tires and operating the control systems in public transport. Medically, they provide clean air for dental tools, ventilators, and oxygen concentrators. Even food/beverage packaging and semiconductor manufacturing rely on clean, stable compressed air.

Simply put, without compressors, modern industrial lines would halt, urban comfort would decline, and many high-tech sectors would lack a critical foundation.

Conclusion

The seemingly straightforward act of "compression" embodies sophisticated mechanical design and fluid dynamics. From the reciprocation of pistons to the rotation of screws and the high-speed spin of impellers, each technological stride has made gas power more efficient, reliable, and economical.

A compressor is more than a device that shrinks gas volume; it is a crucial node converting primary energy into usable power. Through this persistent "compression," it has driven innovation in energy use, advanced manufacturing precision, and elevated medical care, subtly reshaping the limits of time, space, and efficiency to become the true power source of modern industry. As we advance toward intelligent manufacturing and sustainability, this robust "industrial heart" will continue its vital rhythm, propelling progress forward.