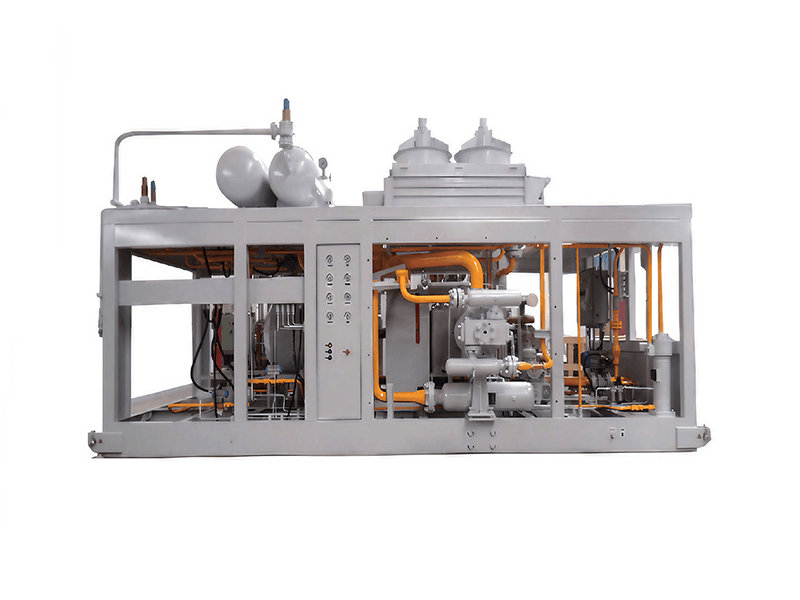

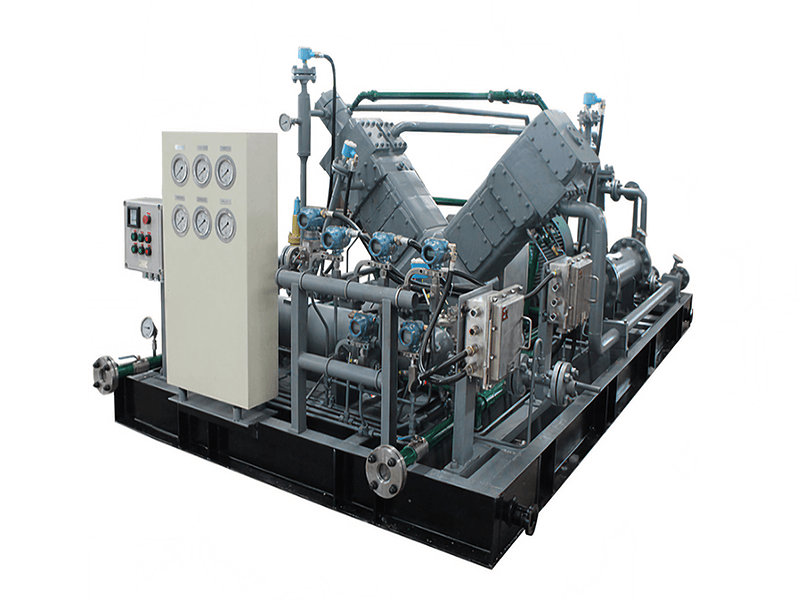

In the grand picture of the green hydrogen industry chain, hydrogen liquefaction compressors are reshaping the energy landscape with their unique technical charm. The essence of this technology lies in the deep coupling of the Brayton cycle and cascade refrigeration - when gaseous hydrogen enters the fourth-stage piston compression system, it will be pressurized to an astonishing 70 MPa, then pass through a vacuum cold box at -253 degrees Celsius, and finally transform into a supercritical liquid. This process breeds triple revolutionary values: its combustion product is only pure water, achieving true zero-carbon release; it contains an energy density of 140 megajoules/kilogram, which is three times the effectiveness of gasoline; it can also directly supply fuel cell systems, opening up the "last mile" of hydrogen energy application.

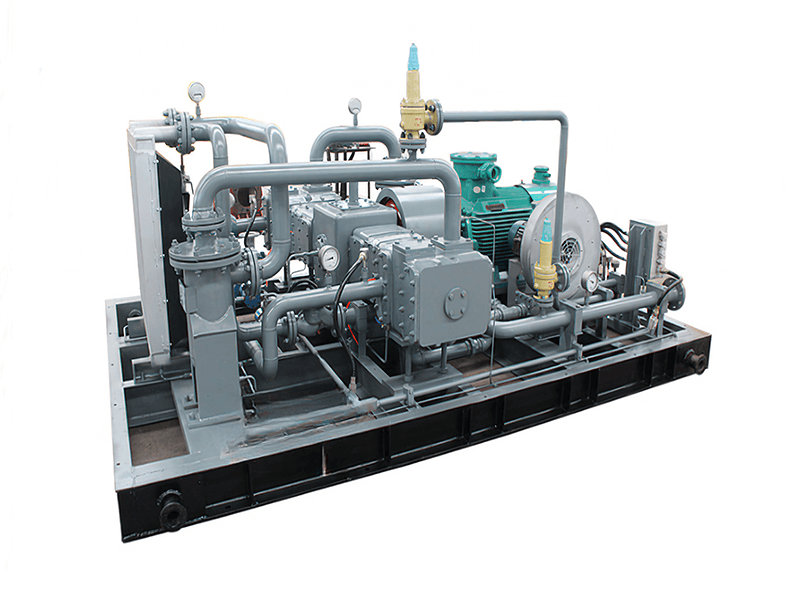

The evolution of technology has never stopped. Germany's Linde Group incorporates magnetic bearing technology into helium refrigeration compressors, compressing vibration losses to less than 5 microns and reducing unit energy consumption to 12 kWh/kg of liquid hydrogen; the nano-sealing coating developed by CIMC Enric has brought the hydrogen leakage rate into the microscopic world of 10 parts per million. These breakthroughs are driving the transformation of liquefied Hydrogen Compressors from precision laboratory instruments to the core artery of hydrogen energy infrastructure. Under the catalysis of the EU Hydrogen Bank plan, 17 countries around the world have launched million-ton green hydrogen projects, and the demand for equipment has shown exponential growth.

Liquid hydrogen storage and transportation: rewriting the code of energy geography

The bottleneck of long-distance energy transportation is being broken by liquid hydrogen. Its volume energy density of 8.5 GJ/m3 is equivalent to six times the transportation efficiency of high-pressure gas hydrogen. The "Hydrogen Pioneer" transport ship of Kawasaki Heavy Industries of Japan is equipped with a three-stage compression system, with a single ship carrying capacity exceeding 125,000 cubic meters, and a 62% drop in transportation costs. What is even more exciting is that in the 100-megawatt energy storage power station led by the German Energy Agency, the liquefied compressor has increased the conversion efficiency of wind power abandonment to 72%, and the cost per kilowatt-hour has been reduced to US$0.19. The "electric-liquid hydrogen" closed-loop system implemented by Siemens Energy in the Netherlands has created a comprehensive conversion efficiency of 54%, and the daily storage and transportation loss of liquid hydrogen is only 0.1%, which is two orders of magnitude better than gaseous transportation. This full-chain synergy makes the compressor a strategic fulcrum for the implementation of the hydrogen economy.

Technical breakthrough: innovative breakthrough at extreme temperatures

Facing the extreme working conditions of -253 degrees Celsius, material scientists developed a chromium-nickel-iron alloy impeller that successfully withstood the drastic temperature difference of 600 degrees Celsius, extending the equipment life to 80,000 hours. The breakthrough in the field of thermodynamics comes from isentropic compression technology, which increases the liquefaction rate by 24% and reduces energy consumption by 18%. The intelligent control dimension has created a predictive maintenance platform with a fault warning accuracy of 99.2%. However, the challenges are still severe: the hydrogen embrittlement effect causes a 40% drop in metal fatigue strength, the cost of a large helium refrigeration unit exceeds 5 million euros, and the daily evaporation rate of liquid hydrogen needs to be controlled within 0.5%. The modular cold box design of Chart Industries in the United States has brought hope, successfully reducing construction costs by 35%, and opening up a feasible path for the industry.

Market explosion: dual-wheel drive of policy and capital

The global liquid hydrogen market is expanding at an annual rate of 27.3%, and demand will exceed 10 million tons in 2030. In the sub-sectors, the compressors supporting hydrogen refueling stations will form a market of 3.2 billion US dollars in 2027, the demand for transport ship compressors will grow by as much as 41%, and the equipment value of a single ship will exceed 30 million US dollars. At the policy level, China's "Medium- and Long-Term Plan for the Hydrogen Energy Industry" clearly states that by 2025, 50 tons/day liquefaction equipment will be localized, and the EU's first batch of 800 million euros in subsidies will focus on liquefaction plants. Traditional giants such as Air Liquide monopolize large projects, innovative companies Hystar deeply cultivate distributed systems, and the capital market has injected 42% of hydrogen energy equipment financing into the field of liquefaction technology.

Winning the future: three strategic commanding heights

When the liquefaction energy consumption exceeds the critical point of 10 kWh/kg, the boundaries of technology application are accelerated. Airbus's liquid hydrogen aircraft engine has achieved -253℃ direct fuel supply, and the utilization rate of liquid hydrogen in the hydrogen-based direct reduction iron process has reached 95%. The technological evolution presents a clear context: the power density of miniaturized compressors exceeds 8 kW/m3, quantum locking technology reduces the daily evaporation rate to 0.01%, and artificial intelligence realizes real-time optimization of dynamic working conditions. For enterprises, it is necessary to focus on the research and development of anti-hydrogen embrittlement composite materials, build an integrated solution of "electrolysis-liquefaction-storage and transportation", and lead the formulation of ISO/TC197 international standards. As the International Hydrogen Energy Commission warns: "The maturity of compressor technology directly determines the steepness of the liquid hydrogen economic cost curve."