In the industrial sector handling flammable and explosive gases, the safety design of compressors is directly related to the reliability of the entire production system and personnel safety. Hydrogen and natural gas, as typical flammable and explosive media, require strict adherence to safety specifications and the adoption of special technical solutions during their compression process. This article systematically elaborates on the relevant explosion-proof certification requirements, key safety technologies, and recommended design schemes.

For compressor equipment used in flammable and explosive environments, compliance with international explosion-proof certification systems is mandatory. ATEX (EU Directive 2014/34/EU) and IECEx (International Electrotechnical Commission Explosive) are two globally recognized authoritative certification standards. According to these standards, equipment for use in explosive atmospheres must meet the following requirements: Equipment must be designed and manufactured according to the zoning of the potentially explosive atmosphere, with Zone 0 requiring the highest level, ensuring that the equipment does not ignite an explosion even during rare malfunctions; Equipment Protection Level (EPL) must reach Ga/Ma level, guaranteeing the equipment does not become an ignition source during normal operation, expected faults, or rare faults; The equipment temperature class must be lower than the ignition temperature of the gas – for example, hydrogen belongs to T1 (ignition temperature >450°C), while natural gas belongs to T3 (ignition temperature >200°C); All electrical and non-electrical equipment needs to pass certification for corresponding types of protection, such as Flameproof (Ex d), Increased Safety (Ex e), or Pressurized (Ex p).

In terms of safety technology, a Nitrogen Inerting System is a crucial measure to ensure the safe operation of the compressor. This system works by injecting nitrogen at a pressure higher than the process gas pressure into potential leak points such as compressor bearing housings and gearboxes, forming an effective gas seal barrier to prevent the leakage of flammable gas or the ingress of air. Nitrogen purity must reach 99.99% or higher, with a dew point temperature below -40°C, and it must be equipped with a pressure interlock control system to ensure the nitrogen pressure is always 0.15-0.3 MPa higher than the process gas pressure. Laser Shaft Alignment technology is key to ensuring reliable equipment operation. Using a laser alignment instrument allows the alignment accuracy between the compressor and the driver to be controlled within 0.05 mm, significantly reducing vibration levels and avoiding friction-induced heating and potential ignition risks caused by misalignment. For leakage monitoring, a multiple detection system is required. This includes distributed combustible gas detectors installed around the compressor with a detection accuracy of 1% LEL; laser methane/hydrogen detectors installed in the seal chambers and bearing housings with a high detection sensitivity of 1 ppm; simultaneously equipped with infrared thermal imagers for regular inspections to promptly detect abnormal hot spots.

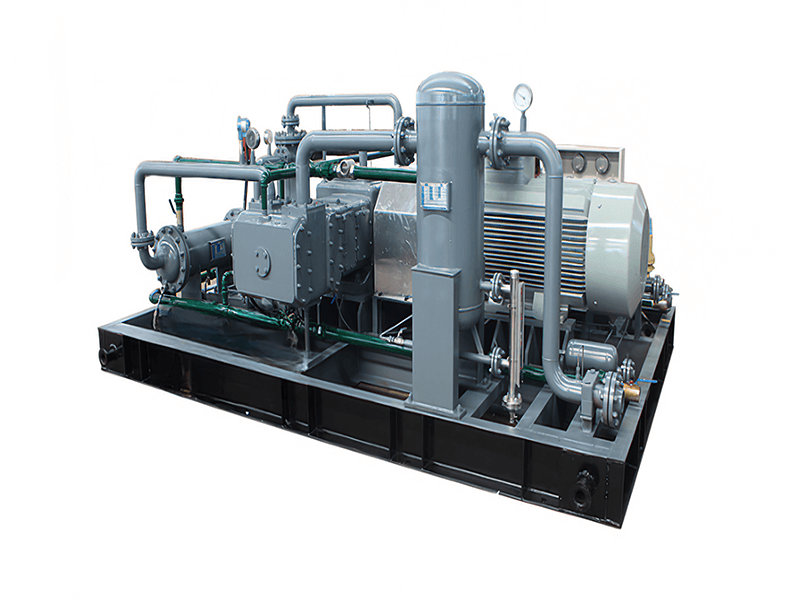

Regarding specific design schemes, Dry Gas Seal systems are the optimal choice for handling flammable and explosive gases. A tandem dry gas seal structure is adopted, where the primary seal bears the entire pressure differential, the secondary seal acts as a backup, and buffer gas (usually nitrogen) is introduced between them, ensuring that flammable gas does not leak to the atmosphere under any circumstances. The seal materials select silicon carbide against graphite as the friction pair; this material combination has self-lubricating properties and does not generate sparks. An Oil-Free Design fundamentally eliminates the risk of lubricating oil contacting the process gas. For hydrogen compression, Ionic Liquid Compressors are recommended, which use incompressible ionic liquid as the piston medium to achieve an isothermal compression process. For natural gas compression, Oil-Free Screw technology can be used, where the rotor surfaces are coated with Polytetrafluoroethylene (PTFE) to ensure a completely oil-free compression process. Additionally, the compressor unit needs to be equipped with a complete safety control system, including an Emergency Shutdown System (ESD) with a response time of less than 100 ms; triple-redundant pressure and temperature sensors; an automatic fire suppression system (typically using carbon dioxide or inert gas); and a lightning protection and electrostatic grounding system with a grounding resistance of less than 4 ohms.

The comprehensive application of these safety designs and technologies constitutes a complete protection system for flammable and explosive gas compressors. In practical engineering applications, personalized design based on specific gas properties, operating parameters, and installation environment is necessary. Furthermore, strict adherence to relevant specifications for installation, commissioning, and periodic inspections is essential to ensure the long-term safe and stable operation of the compressor system.