Selecting a suitable helium compressor requires comprehensive consideration of multiple key technical factors. Due to the unique physical properties of helium, the selection criteria for helium compressors differ significantly from those for traditional air compressors, necessitating special attention to the following technical points. In practical engineering applications, the selection of a helium compressor must be based on an in-depth understanding of its special working mechanism and performance characteristics, while fully considering the process requirements of the specific application scenario.

The selection of the sealing system is central to helium compressor design. Given helium's extremely small molecular diameter and strong permeability, zero-leakage sealing solutions are essential. Dry gas seals are currently the most commonly used technology, achieving complete sealing by introducing seal gas at a pressure higher than the process gas pressure on the process gas side to form a gas barrier. The key to this sealing method lies in maintaining an appropriate seal gas pressure differential, typically requiring the seal gas pressure to be 0.15-0.25 MPa higher than the process gas pressure. Magnetic fluid seal technology is also used in certain special applications, utilizing the special properties of magnetic fluids under magnetic field action to achieve dynamic sealing, capable of achieving very low leakage rates on the order of 10⁻⁹ Pa·m³/s. Labyrinth seals, while simple in structure, are only suitable for applications where high purity is not required due to their inherent leakage. In practical applications, the temperature adaptability of seal materials must also be considered to ensure stable sealing performance within the operating temperature range of -50°C to 200°C.

Material compatibility is another critical factor. While helium itself is inert, it can potentially induce hydrogen embrittlement in materials under high pressure and temperature conditions. Research indicates that when the working pressure exceeds 10 MPa and the temperature is above 150°C, helium can accelerate the material aging process. Therefore, components in contact with helium should be made of high-quality materials such as Austenitic stainless steel 316L, Monel K500, or Hastelloy C276. These materials not only offer excellent corrosion resistance but their microstructures also effectively hinder helium permeation. Seal materials are typically selected from low-permeability polymers such as PTFE and perfluoroelastomers, avoiding the use of standard rubber seals. It is particularly important to note that all surfaces in contact with helium should undergo appropriate surface treatments, such as electropolishing or passivation, to further enhance the material's resistance to permeation.

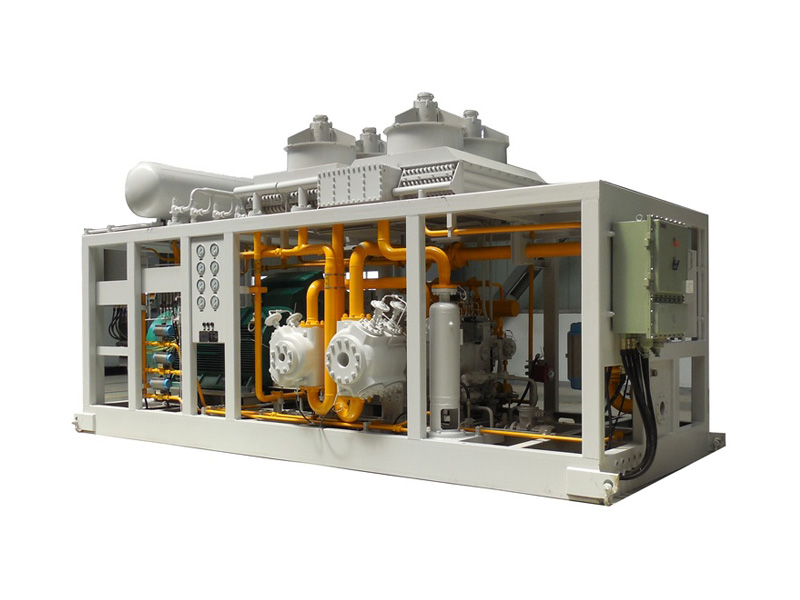

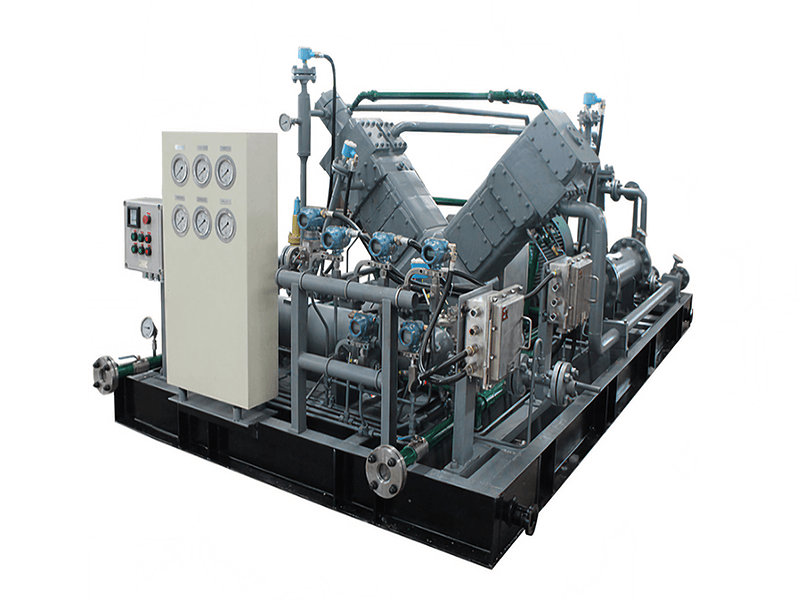

The selection of the compressor configuration is also crucial. For medium-to-low pressure helium compression, oil-free screw compressors are favored for their continuous and stable operating characteristics. The precise clearance control between the male and female rotors (typically 0.05-0.10 mm) effectively reduces internal leakage, while requiring special rotor profile designs to adapt to helium's low density. For applications requiring higher pressures, piston compressors remain the preferred choice, but they require special labyrinth piston designs or the use of liquid ring compression methods. Labyrinth piston compressors form a tortuous leakage path through a series of precision-machined annular grooves, achieving contact-free sealing, making them particularly suitable for high-pressure helium service. Centrifugal compressors are suitable for high-flowrate conditions; however, due to helium's low molecular weight, they require more compression stages and higher rotational speeds, typically demanding impeller tip speeds exceeding 300 m/s.

The design of the cooling system requires special attention. Due to helium's low specific heat ratio, temperature rise during compression is significant, necessitating efficient intercoolers. Plate-fin heat exchangers are commonly used, as their compact structure and high heat transfer performance are particularly suitable for helium service, with heat transfer coefficients reaching 200-400 W/m²·K. Cooling media often include water or special thermal oils, ensuring that the discharge temperature from each stage is controlled below 80°C. For high-power compressors, forced circulation cooling systems should be considered, precisely controlling the flow and temperature of the cooling medium to ensure heat exchange efficiency. System design must also include temperature monitoring points and alarm devices to monitor the temperature rise across compression stages in real-time.

The configuration of the drive system also requires specific consideration. The power requirement for helium compressors is typically 15-25% higher than for air compressors of equivalent flow rate; therefore, sufficient power margin must be allocated during motor selection. Variable Frequency Drive (VFD) is a preferred choice, as it enables soft starting to avoid impact on the sealing system and allows speed adjustment based on actual operating conditions for energy-saving operation. For high-power applications, permanent magnet synchronous motors are recommended, offering efficiency up to IE4 or IE5 class, along with better speed regulation performance. The drive system design must also consider grid harmonic mitigation and power factor correction to ensure compliance with relevant power quality standards.

The control system should include comprehensive monitoring and protection functions. In addition to conventional pressure, temperature, and vibration monitoring, a dedicated helium leak detection system is required. Mass spectrometer leak detectors are typically used, with detection precision up to 10⁻¹² Pa·m³/s, capable of detecting minute helium leaks promptly. Furthermore, a seal gas pressure monitoring system must be installed to ensure the seal gas pressure consistently remains 0.2-0.3 MPa above the process gas pressure. Modern helium compressor control systems should also include intelligent diagnostic functions, analyzing operational data trends to provide early warnings of potential equipment failures. The control system should possess remote monitoring capabilities, supporting data exchange with the plant DCS system for centralized monitoring and intelligent management.

Regarding overall machine design, special attention must be paid to equipment maintainability. Given the high precision requirements of helium compressors, reasonable maintenance access and dedicated tools should be designed to ensure the convenience of maintenance work. For critical components, such as the sealing system and bearings, online monitoring devices should be designed to monitor their operating status in real-time. Simultaneously, it is advisable to establish a comprehensive equipment record, documenting operational data and maintenance history to provide data support for full lifecycle management of the equipment.

Finally, during the equipment installation and commissioning phases, relevant operating procedures must be strictly followed. This includes system purging and leak testing to ensure system cleanliness and leak tightness meet requirements. During commissioning, loading should be gradual, with close monitoring of all operating parameters to ensure the equipment operates under optimal conditions. Through these rigorous technical measures, the long-term stable and reliable operation of the helium compressor system can be ensured.