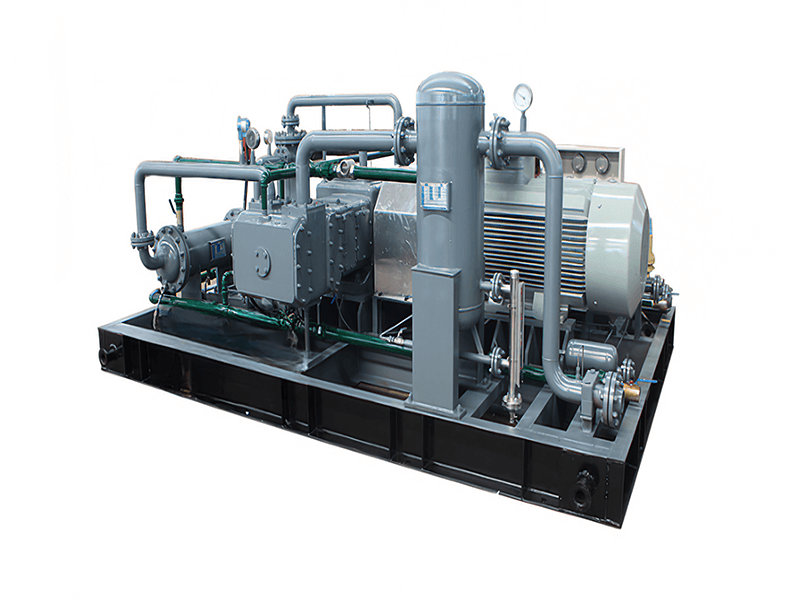

Beside the offshore wind farm in Rudong, Jiangsu, six silver beasts emit a low hum. Every minute, they compress 2700 cubic meters of hydrogen to 45 MPa—equivalent to squeezing the entire volume of a swimming pool into a family car. These oil-free piston compressors are the "heart" of China's largest green hydrogen project, injecting 50 tons of zero-carbon hydrogen into the Yangtze River Delta daily.

I. The "Pressure Engine" of the Hydrogen Artery

In 2019, a fuel cell vehicle exploded suddenly at a test site. The investigation pointed to a compressor valve at the hydrogen refueling station: high-pressure hydrogen had permeated the carbon steel, embrittling the metal like a biscuit. This accident revealed the harshest truth of the hydrogen era: hydrogen molecules, light as a feather, are the ultimate test for industrial equipment.

Three Life-or-Death Compression Challenges:

1. The Battle of the Molecular Cage

Hydrogen molecules are only 0.24 nanometers in diameter—2.6 times smaller than natural gas. When the Beijing Winter Olympics hydrogen station opened, engineers discovered standard seals leaked an average of 2.7% daily—meaning millions worth of hydrogen lost monthly. The solution came from aerospace technology: triple-layer metal bellows seals reduced leakage to one-millionth, equivalent to losing just one can of soda over ten years.

2. Thermal Runaway Alarm

Surveillance footage in 2021 captured a dangerous moment at a German factory: a compressor cylinder suddenly glowed red, thermometers spiking to 285°C (545°F). Hydrogen's adiabatic index is 20% higher than air, causing more intense heating during compression. Intercoolers are now standard, requiring each stage's temperature rise to be controlled within 8°C (14.4°F), like reining in a galloping wild horse.

3. The Hydrogen Embrittlement Corrosion Dilemma

Engineers at Baosteel's hydrogen metallurgy project faced a nightmare: a 316 stainless steel impeller worth millions showed a 32% drop in toughness after just six months in a 40 MPa hydrogen environment. They finally solved it with nickel-based alloy blades coated with a micrometer-thick ceramic layer, blocking hydrogen atom penetration.

II. The Technological Breakthrough Roadmap

1. The "Pressure Staircase" of Refueling Stations

Inside the control room of Shanghai's Anting Hydrogen Station, three compressors run in relay:

First stage: Liquid-driven piston compressor boosts hydrogen from electrolyzers at 1.5 MPa to 15 MPa.

Second stage: Diaphragm compressor finely pressurizes to 45 MPa (99.999% precision).

Third stage: Ionic compressor makes the final sprint to 87 MPa.

This system refuels 60 buses daily, with an error margin less than the weight of a pencil stub.

2. The Digital Code of the Transportation Revolution

CIMC ENRIC's lab conducts extreme tests: a 90 MPa compressor forces hydrogen into carbon fiber storage tanks. When pressure gauges pass the critical point, transport vehicle capacity leaps from 260 kg at traditional 20 MPa to 1100 kg—slashing the per-hundred-kilometer transport cost from 4.2 yuan to 1.8 yuan.

III. Real-World Operations Under the Steel Sky

Long March 5's 600-Second Life-or-Death Test

At the Wenchang Launch Site in 2020, liquid hydrogen fuel was being loaded into the rocket. In the extreme cold of -253°C (-423°F), titanium alloy piston compressors pulsed at 200 times per second, pressurizing liquid hydrogen to 50 MPa. Any seal failure meant explosion. China's self-developed honeycomb sealing technology limited leakage to 0.5 grams per second—equivalent to losing one grain of rice per hour.

Guardian of Zhangjiakou's Winter Olympics

On a freezing night at -32°C (-26°F), sensors at the Taizicheng Hydrogen Station suddenly alarmed: abnormal temperature rise in Compressor 3's bearings. The smart system instantly activated the protocol:

1. Cut off hydrogen supply.

2. Inject nitrogen purge.

3. Switch to the backup unit.

The entire process completed within 28 seconds, ensuring over a hundred hydrogen buses departed on time.

Conclusion: The National Contest on Pressure Gauges

As the global green hydrogen industry explodes, compressors have become strategic choke-point equipment: Japan's Kawasaki Heavy Industries monopolizes 90% of 70 MPa technology; Germany's Bosch holds core patents for liquid-driven compressors. But China is accelerating its breakthroughs—in 2023, domestic ionic compressor market share surpassed 38%, with costs falling from 12 million yuan/unit to 6.8 million yuan.

At the Xianhu Laboratory in Foshan, engineers showcase their latest achievement: a magnetic levitation centrifugal compressor, spinning at 100,000 RPM, slashes hydrogen compression energy consumption by 41%. Outside the window, a hydrogen-powered train speeds toward the future. Behind its smooth operation, countless compressors silently etch the precision and strength of Chinese manufacturing within the high-pressure world.