Application of piston compressors in high-pressure hydrogen delivery systems and analysis of engineering cases

Driven by the global carbon neutrality goal, the strategic position of hydrogen as a zero-carbon energy source is increasing. The high-pressure hydrogen delivery system is the core hub connecting hydrogen production, storage and transportation with terminal applications. Its efficiency and reliability directly affect the large-scale development of the hydrogen energy economy. Piston compressors have become the core equipment for high-pressure hydrogen boosting and delivery with their high pressure ratio, adaptability to variable working conditions and high reliability. However, the unique physicochemical properties of hydrogen (such as low molecular weight, strong permeability, and hydrogen embrittlement effect) pose severe challenges to compressor design. Starting from the technical difficulties, this article analyzes the key technological breakthroughs of piston compressors in high-pressure hydrogen delivery, and explores its engineering practice and future development direction through typical engineering cases at home and abroad.

Ⅰ. Technical challenges of high-pressure hydrogen delivery

1. Hydrogen embrittlement and material failure

Hydrogen molecules easily penetrate into the metal lattice, resulting in a decrease in material toughness (hydrogen embrittlement). Especially under high pressure (≥30MPa), the hydrogen embrittlement sensitivity of carbon steel and low alloy steel increases significantly, threatening equipment safety.

2. High-pressure sealing problem

The diameter of hydrogen molecules is only 0.289nm, and traditional sealing structures are prone to leakage. Under ultra-high pressure conditions above 45MPa, the long-term stability of the dynamic sealing system faces severe tests.

3. Complex thermodynamic properties

Hydrogen has a high adiabatic index (1.41), and the temperature rise of a single-stage compression can reach more than 150°C. Multi-stage compression and efficient cooling control are required to avoid material thermal fatigue and seal aging.

4. Economic bottleneck

The initial investment of high-pressure compressors accounts for 40%~50% of the total cost of the transportation system, and costs need to be reduced through energy efficiency optimization and large-scale production.

Ⅱ. Key technological breakthroughs of piston compressors

1. Anti-hydrogen embrittlement material system

Metal matrix upgrade: The cylinder uses austenitic stainless steel (316L), duplex steel (SAF 2507) or titanium alloy (Ti-6Al-4V), and the hydrogen diffusion coefficient is reduced by 50%~80%.

Surface strengthening technology: The piston rod is sprayed with titanium nitride (TiN) or diamond-like carbon (DLC) coating, with a surface hardness of more than HV2000 and a friction coefficient of less than 0.1.

Optimization of non-metallic parts: The sealing ring is made of carbon fiber reinforced polyetheretherketone (CF/PEEK), with a pressure resistance of 45MPa and a temperature of 180°C.

2. Multi-stage compression and thermal management

Stage configuration: 4~6 stages of compression are adopted, the single-stage compression ratio is ≤2.5, and the total outlet pressure can reach 90MPa.

Interstage cooling design: A plate-fin heat exchanger is configured after each stage, and ethylene glycol solution (-20°C) or liquid nitrogen (-196°C) is used for enhanced cooling, and the outlet temperature is ≤80°C.

Waste heat recovery: Use compression heat for hydrogen storage bottle preheating or regional heating at hydrogen refueling stations, and improve comprehensive energy efficiency by 15%~25%

3. High-pressure sealing technology innovation

Combined sealing system: The main seal uses metal bellows + graphite ring, and the secondary seal is equipped with hydrogen sensitive sensor and hydraulic compensation device, with a leakage rate of ≤10ppm.

Online monitoring network: Integrate laser hydrogen sensor (sensitivity 1ppm) and acoustic emission probe to realize real-time leakage alarm and automatic cutoff.

4. Intelligent operation control

Dynamic load adjustment: Based on model predictive control (MPC), achieve optimal energy efficiency within the load range of 30%~110%.

Digital twin operation and maintenance: Build a three-dimensional virtual model of the compressor, predict the life of the gas valve through vibration and temperature data, and extend the maintenance cycle

III. Analysis of typical engineering cases

Case 1: Japan Hytouch® 90MPa hydrogen refueling station

Background: Provide ultra-high pressure refueling services for fuel cell heavy trucks, with a daily hydrogen refueling capacity of 1.5 tons.

Technical solution:

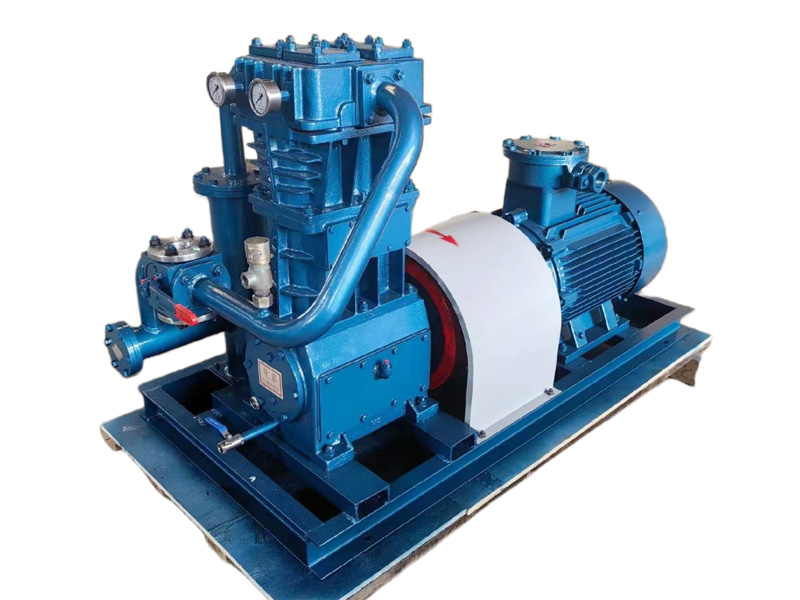

Four-stage oil-free piston compressor, outlet pressure 90MPa, power 220kW, displacement 300Nm³/h.

The inner wall of the cylinder adopts plasma spraying Al₂O₃-TiO₂ composite coating, and the hydrogen embrittlement resistance life reaches 100,000 hours.

The interstage cooling adopts R744 (CO₂) transcritical cycle, and the cooling efficiency is improved by 40%.

Results: Continuous operation for 4 years, leakage rate <0.3%/year, single filling time ≤3 minutes.

Case 2: China's "West-to-East Hydrogen Transmission" Hydrogen Pipeline Phase I Project

Challenge: The world's first cross-regional pure hydrogen pipeline, with a design pressure of 10MPa and a hydrogen transmission capacity of 100,000 tons/year.

Innovative design: 6 20MW electric-driven piston compressors are connected in series, with a single machine pressure ratio of 2.5 and a total outlet pressure of 10MPa.

The piston rod adopts Ti-6Al-4V alloy + WC coating, and the hydrogen embrittlement resistance is improved by 70%.

Equipped with AI energy efficiency optimization platform, dynamic adjustment of compression stages, energy consumption reduced by 12%.

Benefits: Annual reduction of CO₂ by about 2 million tons, supporting hydrogen steelmaking and chemical applications in the Beijing-Tianjin-Hebei region.

Case 3: Germany GET H2® long-distance hydrogen pipeline network

Demand: Build the largest hydrogen energy network in Europe, with a transmission pressure of 30MPa and a total length of 1,300km.

Solution:

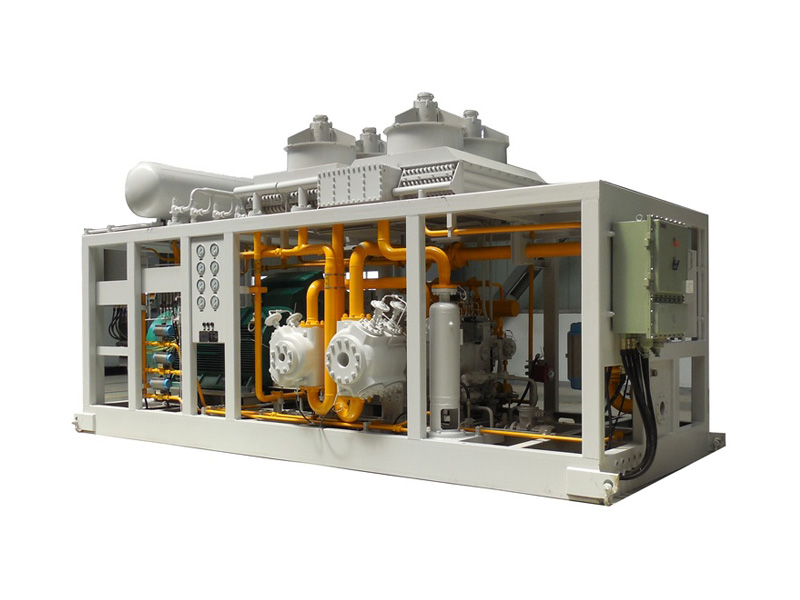

Modular piston compressor unit, single unit power 5MW, support parallel expansion to 50MW.

The sealing system adopts "metal honeycomb + nanographite" structure, with a leakage rate of <5ppm.

Integrated digital twin system, fault prediction accuracy >95%, operation and maintenance costs reduced by 35%.

Results: Annual delivery of 500,000 tons of green hydrogen, replacing 1.5 billion cubic meters of natural gas consumption.

IV. Industry Challenges and Countermeasures

1. Insufficient long-term effectiveness of ultra-high pressure sealing

Countermeasures: Develop metal organic framework (MOF) coating sealing materials, reducing hydrogen permeability by 90%.

2. Insufficient coordination of hydrogen energy infrastructure

Countermeasures: Promote the integrated standard of "hydrogen production-compression-storage and transportation" to shorten the equipment adaptation cycle.

3. Urgent need for economic optimization

Countermeasures: Promote 25MPa/45MPa universal compression modules, and reduce costs by 30% through large-scale production.

V. Future development trends

100MPa-level ultra-high pressure technology: Break through the bottleneck of liquid hydrogen storage and transportation and aerospace applications.

Green electric direct drive system: Couple photovoltaic/wind power to build a zero-carbon compression station.

Hydrogen-natural gas mixed transportation: Develop compressor materials and control algorithms that are suitable for 10%~30% hydrogen blending ratio.

Independent technological breakthroughs: Overcome "bottleneck" links such as hydrogen embrittlement-resistant alloys and high-precision seals.

Conclusion

Piston compressors bear the core functions of pressurization, pressure regulation and safety assurance in high-pressure hydrogen transportation systems. Through the innovation of anti-hydrogen embrittlement materials, multi-level thermal management optimization and the construction of intelligent operation and maintenance systems, its application in scenarios such as long-distance pipelines and hydrogen refueling stations has achieved remarkable results. Engineering practices in Japan, China and Germany have shown that high-reliability design and modular concepts can greatly improve the economic efficiency of the system. In the future, with the deep integration of ultra-high pressure technology and green electricity, piston compressors will become the core support for large-scale hydrogen transportation and accelerate the green transformation of the global energy structure.