With the transition of global energy structure to green and low-carbon, hydrogen energy, as a zero-carbon energy carrier, is accelerating the expansion of its application in industry, transportation, energy storage and other fields. Scale storage and transportation of hydrogen is the key link to realize hydrogen energy economy, while compression technology is one of the core of the storage and transportation chain. Piston compressors occupy an important position in hydrogen compression, hydrogen refueling stations and long-tube trailer transportation due to their advantages of high pressure ratio, flexible adjustment and reliability. However, the characteristics of hydrogen, such as small molecular weight, high permeability, and susceptibility to hydrogen embrittlement of materials, pose unique challenges to compressor design. This paper analyzes the key technological breakthroughs of piston compressors in light of the technological needs of hydrogen storage and transportation, and discusses their engineering practice and future development direction through typical cases at home and abroad.

I. Technical characteristics and challenges of hydrogen storage and transportation

1. Hydrogen physical and chemical characteristics of the technical difficulties brought about by

Low molecular weight and high permeability: the molecular diameter of hydrogen is only 0.289nm, easy to leak through the sealing gap, the compressor sealing system is very demanding.

Risk of hydrogen embrittlement: High-pressure hydrogen can easily penetrate into the metal lattice, leading to material embrittlement, especially in carbon and low-alloy steels.

Significant compression temperature rise: Hydrogen has a high adiabatic index (1.41), and the temperature rise during compression is dramatic, with a single-stage compression temperature rise up to 150°C or more, requiring multi-stage cooling control.

2. Diversified requirements of storage and transportation scenarios

Hydrogen refueling station: Hydrogen needs to be pressurized from 20MPa to 45MPa or 90MPa (on-board hydrogen storage cylinder pressure).

Long-tube trailer transportation: Hydrogen is usually compressed at 20-30MPa, requiring efficient compressor start/stop.

Green Hydrogen Storage: In line with the volatility of renewable energy sources, the compressor needs to have a wide load regulation capability.

II. Key Technologies of Piston Compressor in Hydrogen Storage and Transportation

1 anti-hydrogen embrittlement materials and surface treatment

Substrate material selection: Cylinders and valves are made of austenitic stainless steel (e.g., 316L), duplex steel (SAF 2507), or titanium alloy (Ti-6Al-4V) to inhibit hydrogen atom penetration.

Coating technology: Piston rod surfaces are sprayed with titanium nitride (TiN) or ceramic coatings (Al₂O₃) to reduce friction and block hydrogen diffusion.

Non-metallic seals: Polyether ether ether ketone (PEEK) or graphite composite materials are used, combining low permeability and high temperature resistance (≤200°C).

2. Multi-stage compression and efficient cooling system

Optimization of the number of stages: design 4~6 stages of compression, single-stage compression ratio ≤ 3.0, to avoid the degradation of material properties caused by high temperature rise.

Cooling program between stages: using plate-fin heat exchanger and low-temperature water circulation (5 ~ 10 ℃), to control the outlet temperature of each stage ≤ 100 ℃.

Waste heat utilization: Recycling of compression heat for preheating or district heating in the hydrogenation station, improving the comprehensive energy efficiency by 10%~20%.

3. Highly reliable sealing system

Combined sealing design: the main seal adopts “metal bellows + graphite ring”, and the secondary seal is equipped with hydrogen sensor for emergency sealing compensation.

Online leakage monitoring: laser hydrogen sensor (detection limit ≤ 1ppm) is arranged in the compressor chamber and connecting flange, realizing second leakage response.

4. Intelligent control and operation and maintenance

Adaptive pressure regulation: Dynamically adjust the number of compressor stages and speed through model predictive control (MPC) to adapt to fluctuations in hydrogen demand.

Digital twin system: builds a 3D virtual model of the compressor, maps vibration and temperature data in real time, and predicts the remaining life of key components.

III. Typical Engineering Case Analysis

Case 1: Hydrogen refueling station in Tokyo, Japan (Eneos-Sovereign project)

Background: The world's first commercialized 70MPa hydrogen refueling station, with a daily refueling capacity of 1000kg, serving fuel cell trucks.

Technical Program:

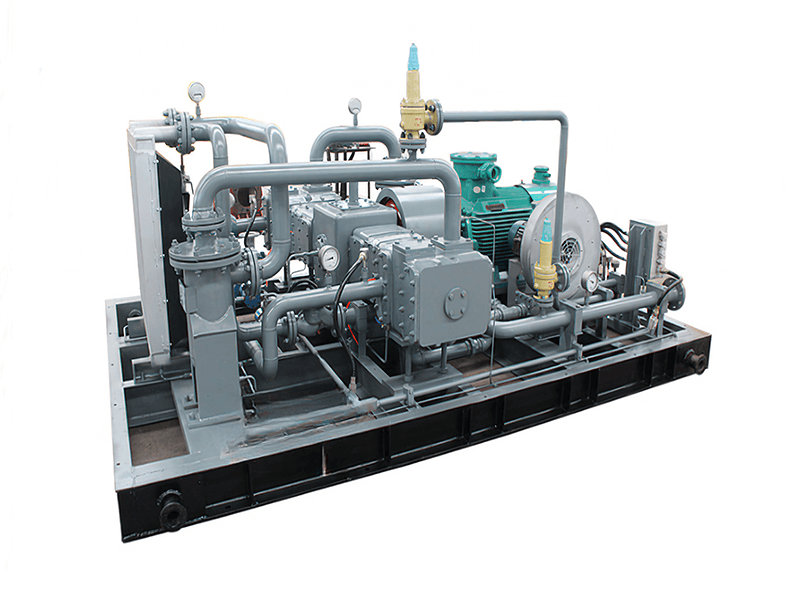

A four-stage oil-lubricated piston compressor is used with an outlet pressure of 90MPa and a motor power of 160kW.

The cylinder is made of 316L stainless steel lined with ceramic coating, and the sealing system integrates double-layer graphite rings with infrared leakage monitoring.

R744 (CO₂) refrigerant is used for interstage cooling, and the outlet temperature is stabilized below 45℃.

Effectiveness: 3 years of continuous operation, leakage rate <0.5%/year, single hydrogenation time reduced to 5 minutes.

Case 2: Zhangjiakou Green Hydrogen Storage Project, China

Challenge: High volatility of wind power hydrogen production, compressor needs to adapt to frequent switching of 30%~120% load.

Innovative design:

Equipped with permanent magnet synchronous motor and four-quadrant inverter to achieve load response within 0.5 seconds.

Modularized compressor set: 3 sets of 10MPa compressors are connected in parallel, supporting flexible configuration of “one use, two backups”.

Applying AI scheduling algorithm, adjusting the compression plan in advance according to the wind power forecast, reducing energy consumption by 12%.

Benefits: 12,000 tons of hydrogen compression per year, with 200MW wind farm, reducing CO₂ emission by about 100,000 tons/year.

Case 3: HyComp® High Pressure Hydrogen Transmission Project in Germany

Requirement: Compress hydrogen from electrolyzer (1.5 MPa) to 30 MPa and inject into long-distance pipeline.

Solution:

Five-stage oil-free piston compressor with a single displacement of 500Nm³/h and an outlet pressure of 30MPa.

Piston rings are made of carbon fiber reinforced PTFE, reducing the coefficient of friction by 40% and achieving lifetime lubrication-free.

Integration of the Internet of Things (IoT) platform to remotely monitor the status of the compressor group, reducing operation and maintenance costs by 30%.

Results: The project covers the Ruhr industrial area, with an annual hydrogen delivery capacity of 40,000 tons, supporting the transformation of hydrogen steelmaking in steel mills.

IV. Industry Challenges and Strategies

1. Insufficient long-lasting high-pressure seals

Countermeasure: R&D of Metal Organic Framework (MOF) coated sealing materials with hydrogen permeability reduced by 90% compared to traditional materials.

2. High initial investment cost

Countermeasure: Promote standardized compression modules (e.g., 25MPa/45MPa universal head), and scale production to reduce costs by 25%~40%.

3. Hydrogen infrastructure is not perfect

Countermeasures: the development of “hydrogen production - compression - storage and transportation” integrated solutions to shorten the industry chain supporting cycle.

V. Future development trend

Ultra-high-pressure technology breakthrough: the research and development of 100MPa compressor to support the liquid hydrogen storage and transportation and aerospace needs.

Green power direct-drive integration: build “photovoltaic/wind power-electrolyzer-compressor” zero-carbon compression system, realizing the decarbonization of the whole chain.

Hydrogen-Natural Gas Mixed Transportation: Optimize compressor materials and control system to adapt to mixed gases with hydrogen doping ratio of 10%~20%.

Autonomous and controllable technology: breakthroughs in high-performance sealing materials, hydrogen-brittle alloys and other “choke points” to promote localization and substitution.

Conclusion

Piston compressors play a central role in hydrogen storage and transportation in terms of pressurization, peak regulation and safety assurance. Through the innovation of anti-hydrogen embrittlement materials, multi-stage cooling optimization and intelligent control, their application in hydrogen refueling stations, long tube trailers and other scenarios has achieved remarkable results. Japan, Germany and other international cases show that high reliability design and modularization concept can effectively reduce the whole life cycle cost. In the future, with the deepening of the synergy between UHP technology and green power, the piston compressor will become the key support for the large-scale application of hydrogen energy, helping to achieve the global carbon neutral goal.