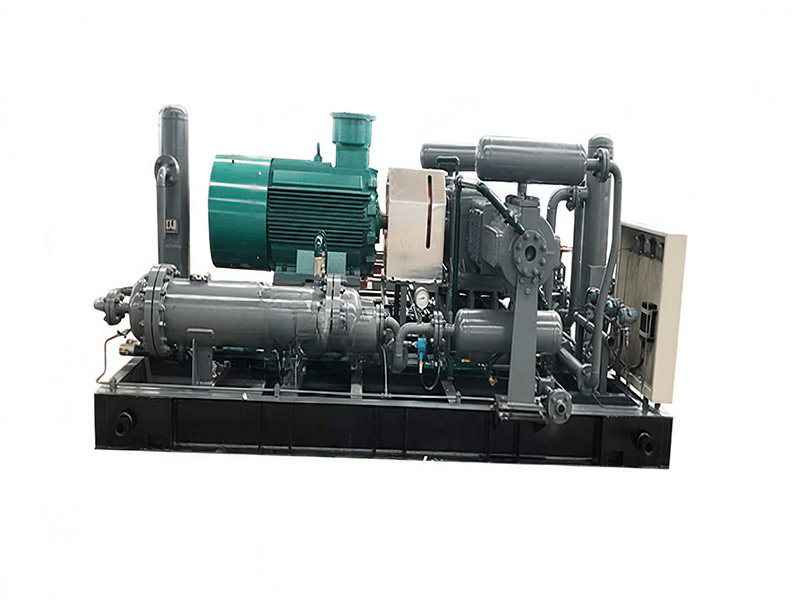

As a typical representative of turbocompressors, centrifugal compressors are indispensable key equipment in modern large-scale industrial plants. According to the international standard ISO 5389, a centrifugal compressor is a type of turbomachinery that uses rotating impellers to perform work on a gas, simultaneously increasing its pressure and velocity. Its widespread application in industries such as petroleum and chemical processing, metallurgy, and air separation makes it a core power source ensuring continuous production.

Working Principle and Technical Characteristics

The working principle of centrifugal compressors is based on gas dynamics. Gas enters the compressor's inlet guide vanes axially, acquires kinetic energy through high-speed rotating impellers (typically operating at 3000-20,000 rpm), then enters a diffuser where the flow passage area gradually increases. This causes the gas velocity to decrease, converting kinetic energy into pressure energy. Finally, the high-pressure gas is collected and discharged via the volute.

This operational method confers the following significant advantages: Firstly, a wide single-unit flow range with handling capacities reaching 1000-500,000 m³/h. Secondly, continuous flow operation ensures smooth, pulse-free discharge airflow with pressure fluctuations less than 1%. Thirdly, the unit structure is compact with a small footprint, and vibration velocity is typically below 2.8 mm/s. Fourthly, the use of oil-film bearings or magnetic bearings achieves mechanical efficiency of over 95%.

Application Fields and Media Adaptability

In terms of media adaptability, centrifugal compressors are primarily suitable for large-volume air compression and the handling of various process gases. In air separation plants, they are used to compress atmospheric air with flows reaching over 100,000 m³/h. In petroleum refining processes, they handle catalytic cracking gases within a pressure range of 0.8-3.5 MPa. In the metallurgical industry, they are used for blast furnace blowing with air volumes up to 8,000 m³/min. In the chemical sector, they are employed for gas compression in production processes like ammonia and methanol synthesis, with discharge pressures reaching up to 15 MPa.

It is particularly important to note that centrifugal compressors have specific requirements for gas properties. They are suitable for gases with molecular weights between 10-50. For low molecular weight gases (such as hydrogen), a multi-stage compression design is required. Furthermore, the compressor's performance curve indicates that the flow regulation range is typically 70%-110%. Operating outside this range may induce surge or choke conditions.

Technical Limitations and Selection Considerations

It must be specifically stated that centrifugal compressors have defined application boundaries. When the gas flow rate falls below 300 m³/min, impeller efficiency decreases significantly, and specific power consumption increases by over 15%. Under low-flow conditions, surge can also occur, seriously affecting equipment operational safety. Therefore, this type of machine is not suitable for applications requiring low flow and high pressure ratios.

Selecting a centrifugal compressor requires consideration of several key technical parameters: Firstly, inlet conditions including pressure, temperature, and humidity. Secondly, flow requirements, necessitating accurate calculation of the process's maximum, minimum, and normal flow rates. Thirdly, discharge pressure requirements, taking into account system resistance losses. Finally, gas composition characteristics, including molecular weight, isentropic exponent, and compressibility factor. Correct selection not only impacts equipment operating efficiency but also directly influences the stability and economy of the entire process system.

Innovation and Development Trends

Modern centrifugal compressor technology is evolving towards intelligence and higher efficiency. The adoption of three-dimensional impeller designs can improve efficiency by 5-8% compared to traditional impellers. The application of magnetic bearing technology enables completely oil-free operation. Equipped with intelligent control systems, they can monitor operating status in real time, provide automatic anti-surge control, and optimize operational efficiency. These technological innovations further expand the applicable range of centrifugal compressors and significantly enhance operational reliability.

If you are planning a large-scale industrial project requiring high-volume gas compression, our professional technical team can provide complete centrifugal compressor solutions. We offer comprehensive technical services including process calculation, equipment selection, installation, and commissioning. Please visit our official website for detailed technical information or to schedule a technical discussion with an engineer.

Note: The technical parameters mentioned herein are based on industry general standards. Specific equipment selection requires professional calculation and evaluation according to actual operating conditions. Final equipment performance shall be subject to the performance curves and data sheets provided by the manufacturer.