As a typical representative of positive displacement compressors, screw compressors have become the most widely used type of air compressor in the industrial field today. Defined by the international standard ISO 1217, screw compressors achieve gas compression through the rotation of two intermeshing rotors within a housing, playing a crucial role in modern manufacturing. As the core power source for factory pneumatic systems, screw compressors provide stable and reliable air supplyguarantee for various pneumatic equipment, automated production lines, and process flows, making them indispensable key equipment in the field of industrial automation.

Working Principle and Technical Characteristics

Screw compressors employ the positive displacement compression principle, utilizing a pair of precisely machined male and female rotors that rotate in opposite directions within a housing to achieve continuous gas compression. The male rotor typically has 4 helical lobes, while the female rotor has 6 flutes; they rotate together at a specific speed ratio (typically 4:6 or 5:6). The rotor profile design utilizes advanced symmetrical arc profiles or asymmetrical profiles, such as Sigma, Alpha, and other high-efficiency profiles. These profiles are optimized through calculation to minimize internal leakage and maximize volumetric efficiency.

As the rotors turn, the volume of the flute at the suction end gradually increases, creating a vacuum to draw in gas; subsequently, the flute volume gradually decreases, compressing the gas; finally, the gas is discharged at the discharge end upon reaching the predetermined pressure. The entire compression process is divided into four stages: suction, closure, compression, and discharge, characterized by smooth airflow and minimal pressure fluctuation (typically less than 0.1 bar). Modern screw compressors often adopt a three-stage compression design, with a compression ratio controlled between 3:1 and 4:1 per stage to ensure optimal thermodynamic and mechanical efficiency.

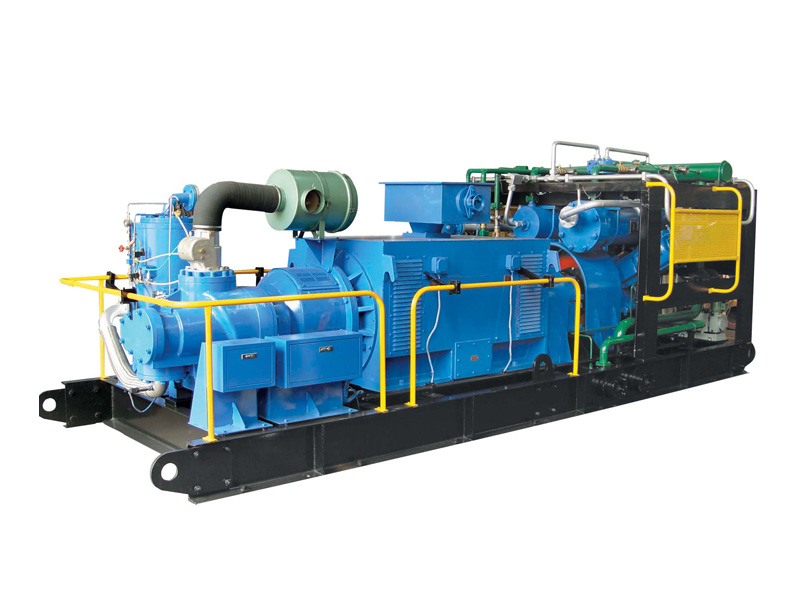

This type of compressor offers several significant technical advantages: Firstly, its compact structure and integrated design reduce the footprint by over 40% compared to piston compressors of equivalent specification. Secondly, it operates smoothly with a vibration intensity typically below 2.5 mm/s, requiring no special foundation and allowing direct installation on standard flooring. Thirdly, it features excellent noise control, utilizing a double-layer acoustic enclosure and efficient silencers to maintain noise levels between 65-75 dB(A). Fourthly, maintenance is simple, and operational cycles are long, typically reaching 8,000-10,000 hours before routine maintenance is required.

Energy Efficiency Performance and Energy-Saving Technologies

Modern screw compressors demonstrate outstanding energy efficiency. The adoption of advanced profile designs and precise manufacturing processes enables volumetric efficiency to reach over 95% and adiabatic efficiency to reach 80-85%. The specific power index is significantly optimized; the specific power of standard oil-injected screw compressors can reach 5.8~6.2 kW/(m³/min), while that of permanent magnet variable frequency models can even be reduced to 5.4~5.8 kW/(m³/min).

The application of variable frequency technology is a major breakthrough in energy saving for screw compressors. By utilizing Variable Frequency Drive (VFD) technology, the compressor can automatically adjust the motor speed according to the actual air consumption, ensuring precise matching of discharge volume to air demand. This technology is particularly suitable for applications with significant fluctuations in air consumption, eliminating energy waste during no-load operation. Measured data indicates that variable frequency screw compressors can save 20%-35% more energy than fixed-speed models under partial load conditions (40%-80% load).

Furthermore, modern screw compressors incorporate multiple energy-saving technologies: including high-efficiency permanent magnet synchronous motors (reaching IE4 or IE5 efficiency classes), heat recovery systems (capable of recovering over 90% of compression heat), and intelligent control systems (enabling multi-unit coordination and optimal operational strategies). The comprehensive application of these technologies improves the annual operational efficiency of modern screw compressors by over 25% compared to traditional models.

Media Adaptability and Application Fields

In terms of media adaptability, screw compressors are primarily suitable for air compression. They can be classified into three main categories based on the processing medium: oil-injected, oil-free, and special gas compressors. Oil-injected screw compressors are mainly used for general industrial compressed air and are the primary source of air power equipment in manufacturing, textiles, food and beverage, and other industries. Oil-free screw compressors utilize special materials and sealing technologies to provide ISO 8573-1 Class 0 oil-free air, widely used in pharmaceuticals, electronics, food, and other industries with stringent air quality requirements.

Additionally, they have important applications in special working media: compressing environmentally friendly refrigerants like R134a and R410A in refrigeration; compressing process gases like natural gas and refinery gas in petrochemicals; and compressing unconventional gases like biogas and coalbed methane in the energy sector. The working pressure range is typically 0.7~1.3 MPa, with special designs reaching above 4.0 MPa, and the flow rate range covers 1~150 m³/min.

Screw compressors are widely used in the following fields: providing power for pneumatic tools, painting equipment, and assembly lines in automotive manufacturing; for packaging equipment, filling lines, and cleaning systems in the food and beverage industry; supplying air sources for spinning machines, looms, and dyeing and finishing equipment in the textile industry; and for cleanroom environments, PCB manufacturing, and component testing equipment in the electronics industry. Depending on application requirements, different configurations can be chosen, including stationary, mobile, cabinet-type, and pipeline-type structural forms.

Equipment Selection and Technical Specifications

Key technical parameters to consider during equipment selection include: firstly, determining the working pressure requirement, typically adding a 0.1-0.2 MPa margin; secondly, calculating the maximum air consumption, considering the simultaneous usage factor and leakage factor; thirdly, analyzing air consumption fluctuations to decide whether a variable frequency model is needed; fourthly, clarifying air quality requirements to determine the necessary filtration grade and drying method; and finally, evaluating installation environmental conditions, including ambient temperature, altitude, and cooling method.

Detailed techno-economic analysis is also required during the selection process: including initial investment cost, electricity consumption cost (accounting for about 70% of the life cycle cost), maintenance costs, and expected equipment lifespan. It is recommended to use the Life Cycle Cost (LCC) analysis method for comprehensive evaluation. Typically, choosing equipment with a higher energy efficiency class, though involving a higher initial investment, can recover the investment difference within 2-3 years through reduced operating costs.

According to international standards such as ISO 1217, GB/T 19432, and other specifications, the main performance parameters of screw compressors should include: rated discharge volume (calculated based on intake conditions), rated working pressure, specific power index, noise level, and vibration intensity. Attention should also be paid to the environmental performance of the equipment, including the use of refrigerants (prefer environmentally friendly refrigerants like R134a), material recyclability (should reach over 95%), and environmental management system certification during production (such as ISO 14001).

Technology Development Trends and Innovation Directions

Current screw compressor technology is developing towards higher efficiency, intelligence, and integration. In terms of efficiency, the application of permanent magnet variable frequency technology improves part-load efficiency by over 20%; the development of new asymmetric rotor profiles increases volumetric efficiency by 3%-5%; and the application of air bearing technology enables completely oil-free operation. In terms of intelligence, the application of IoT technology enables remote monitoring, predictive maintenance, and energy efficiency management; the introduction of artificial intelligence algorithms allows multi-unit control systems to automatically optimize operational strategies.

In terms of system integration, modern screw compressors increasingly adopt integrated designs, combining the compressor, dryer, filters, etc., into a compact system, reducing installation space and pressure losses. Meanwhile, the development of energy management systems enables compressed air systems to coordinate and optimize with other factory energy systems, achieving maximum overall energy efficiency.

If you are planning a new factory or upgrading an existing compressed air system, choosing high-efficiency screw compressors is a critical first step towards energy saving and cost reduction. We provide complete screw compressor solutions, including equipment selection, system design, installation, commissioning, and after-sales service. Our professional technical team can provide tailored optimization solutions based on your specific needs, helping you achieve optimal energy utilization efficiency. Welcome to view our product series to obtain detailed technical information and customized solutions.

Note: The technical parameters described in this article are based on industry general standards. Specific equipment performance is subject to the technical data provided by the manufacturer. Equipment selection is recommended to be conducted in consultation with professional technical personnel for detailed calculation and evaluation, considering specific factors such as local climate conditions and electricity price policies.